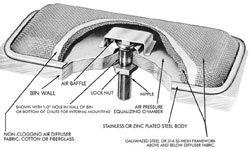

Bin-Flo Aerators

An aerator is

a simple and efficient means of introducing low pressure

air into any dry finely ground material. The air is equally

distributed in controlled quantities to give the material

an ability to flow by gravity from bins, hoppers or chutes.

Aerators incorporate non-cloggin diffusers, integral orifice

and construction features which insure long, maintenance-free

life.

Typeical applications

include: gypsum, Portland cement, bentonite, casein glue,

fuller's earth, soda ash, lime, flour, bran, clay, sawdust,

carbon black, chemicals, barites, ore, feed, cereals, diatomaceous

earth, pigments, soap powder detergents, fly ash and plastic

moulding compounds.

Features and Benefits:

- Can be installed from inside or outside

of the bin

- Only one drilled hole needed per pad —

easy installation

- Integral orifice — controls

air consumption at any recommended pressure

- Non-clogging diffuser — provides

equal ditribution of air; will not clog when air is on

with even the finest materials.

Tank Nipple: |

“L” Series, 1/8” (3mm)

brass, “LL” Series, 1/4” (6mm) plated

steel |

Spacer Washers: |

Nickel plated steel |

Diffuser Frame: |

Up to 180°F (82°C)

cotton (canvas)

Up to 600°F (316°C) fiberglass |

Diffuser Frame: |

Galvanized steel 16 mesh or stainless

steel mesh type 316 |

Body: |

Zinc plated steel or stainless steel |

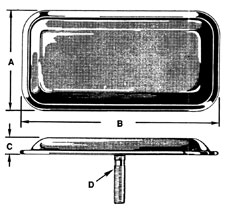

.Dimensions:

|

“L” Series |

“LL” Series |

A |

3

3/4” |

6” |

B |

7

1/2” |

12” |

C |

7/16” |

11/16” |

D |

1/8” x

2” |

1/4” x

2” |

"LL" Series has a diffusin area approximately

2 1/2 times that of the "L" Series. When installed

in larger bins, it will reduce the number of aerators and the

amount of piping required.

How to Order:

Diffuser |

Diffuser Supported

by |

Body |

Model Number |

“L” Series |

“LL” Series |

3 3/4” x 7 1/2” |

6” x 12” |

Cotton (Canvas) |

Galvanized Steel 16 Mesh |

Zinc Plated Steel |

L

LBF900000 |

LL

LLF900000 |

Stainless

Steel

Mesh Type 316 |

Stainless Steel |

L-SS

LBF900002 |

LL-SS

LLF900002 |

Fiberglass |

Galvanized Steel 16 Mesh |

Zinc Plated Steel |

L-FG

LBF900001 |

LL-FG

LLF900001 |

Stainless Steel

Mesh Type

316 |

Stainless Steel |

L-SS-FG

LBF900003 |

LL-SS-FG

LLF900003 |

Air Supply:

The best and usualy the most economical

air supply is from a positive displacement low pressure blower.

For test applications or applications involvig less than

30 CFM, compressors may be used with a pressure reducing

regulator and filter or moisture trap on the low pressure

side. This table shoes the volume of air one Bin-Flo® aerator

(uncovered) will use at various operating pressures.

Important Notes:

a continous air supply mst be maintained at all times to ensure

proper operation of the aerator. Lack of air supply will cause

material to build up o aerator and result in damage.

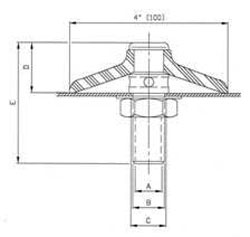

Silo Fluidizer

Disks

Features:

- Aeration — loosens up the product allowing

it to flow easier. Miniumum back pressure puts air energy

where it is needed the most—in the silo.

- Directional Air Flow — The fluidizer disk

forces air to move aong the bin wall freeing up product and

assuring good clean-out.

- Gentle Vibration — keeps the product

flowing ith-out allowing it to compact or plug.

- No Airline Plugging — the patented

disk seals tightly against the sio wall and prevents airline

plugging.

forces air to move along the bin wall, freeing product, assuring

good clean-out.

- Robust Design —The disk will not

tear, pick up moisture and is unaffected by temperatures

up to 350F (170C).

- Material Compatible—Si;licone rubber

standard in blue or whilte (both are food grade approved),

or black or white EPDM.

Technical Data:

Series 4300: Capacity

10-20 CFM @ 20-30 PSI

Model |

Disk |

Stem |

A |

B |

C |

D |

E |

Airline Options |

4300 |

Blue |

Mild Steel |

1/4” NPT |

1/2” NPT |

7/8” NPT |

1

3/16” NPT |

3” NPT |

3/8” -

1/2” (10-13mm) Tubing |

4301 |

White |

4302 |

Blue |

Aluminum |

4303 |

White |

4304 |

Blue |

Stainless |

4305 |

White |

Series 4400: Capacity 25-40 CFM @ 10-20 PSI

Model |

Disk |

Stem |

A |

B |

C |

D |

E |

Airline Options |

4400 |

Blue |

Mild Steel |

1/2” NPT

or BSTPT |

3/4” NPT |

1

1/16”

(27mm) |

1

1/4”

(32mm) |

3

1/16” (78mm) |

1/2” -

3/4” (13-19mm) Tubing or Hose |

4401 |

White |

4402 |

Blue |

Aluminum |

4403 |

White |

4404 |

Blue |

Stainless |

4405 |

White |

Series 4500: Capacity 30-50 CFM @ 5-10 PSI

Model |

Disk |

Stem |

A |

B |

C |

D |

E |

Airline Options |

4500 |

Blue |

Mild Steel |

3/4” NPT

or BSTPT |

1” NPT |

1

3/8”

(35mm) |

1

1/4”

(32mm) |

3

1/4” (83mm) |

3/4” -

1”

(19-25mm) Hose |

4501 |

White |

4502 |

Blue |

Aluminum |

4503 |

White |

4504 |

Blue |

Stainless |

4505 |

White |

Versatility

numerous combinations of stems, fittings and airlines to fit your application. Can be used with highpressure/low volume compressed air or with low pressure/ high volume blower air.

Engineering Assistance

Fax or email a sketch or drawing of your bin, along with a description

of your bulk material and we will provide a recommended number

and placement of fluidizers for your application.

Easy Installation

fits both conical and square bins, EZ-In (Easy-In) kits also

available for installation without getting inside the bin.