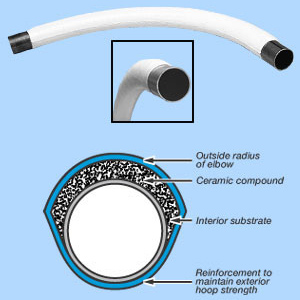

Ceramic-Lined Bends and Straights

These have a uniform coating of a specially formulated ceramic material that is added to the inside diameter of the bend to give it a very hard, slippery, glass-like surface. The hardness of the ceramic coating is between 5 and 6 on the Mohs Scale – as hard as glass and just as smooth. The exterior of the bend has the appearance of annealed steel and can be easily painted.