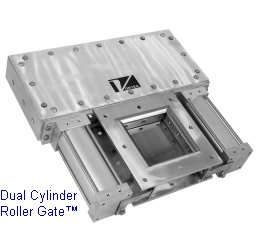

Vortex Dual Cylinder Roller Gate

• Excellent for limited space requirements

• Dust tight material seal

• Gravity and low pressure applications

• 6″ – 30″ square or rectangular sizes

• Metric Sizes Available

• Designed specifically to handle dry material.

Dual cylinder design reduces overall length by one third. With the Vortex Dual Cylinder Roller Gate valve, there is no metal on metal contact between the blade and the valve body. This feature eliminates the associated gate seizing and binding seen with other slide gate valves.